| Home

Brew CW Filter:

If you are just getting

into CW and you are starting off with an older radio or

QRP set. Newer

radios may come equipped with filters for

narrowing the audio passband or digital signal processing (DSP) to

clean up unwanted noise.

But you may be faced with trying to pick out a wanted signal from a

swamp of others.

This is because the band width of your receiver's audio passband is too

wide and other nearby signals are competing for your ears.

What you need to do is just pick out one single CW signal.

This little accessory will add the much needed narrow band filtering to

your audio radio's output.

The circuit used is an active RC driven filter using Op amps and is

pre-constructed for a set frequency range.

The circuit was inspired from the ARRL Extra Class study manual's

(Volume 8) pages on active filters.

This device has a narrow pass band that will amplify only a desired

range or audio frequencies and reject other that may contain QRM

& QRN.

The circuit is small enough to be tucked away inside of many older

rigs. The ouput is enough to drive a pair of headphones or a small PM

speaker.

This project was stuffed into

a small Altoids® mint tin.

(Click

to enlarge photos)

Building your own

station accessories is a time honored tradition of ham radio. There is

more satisfaction and learning that comes from "home-brewing" over that

of just ordering an "appliance" from a catalog.

If you would like to construct your own, you should have some basic

knowledge of electronics , being familiar with IC's and audio

circuitry. If you are a ham, this should come naturally.

A lot of trial and error went into my own construction of this and I do

not profess to being an expert.

If you'd like to buy one commercially made or find a kit there are some

available out there, one for $40, as it may be more worth while to

construct your own using high-grade parts and pre-etched PCB's. Just

search for "CW

Filter" in Google. Kits are a great way to help you learn

electronics.

Operation:

This is how I use the filter: I plug an audio

patch cord (commonly found at Walmart) between the rig's phone

jack and the input of the filter. If the rig's output is in stereo,

then add an adapter.

Because of the switch I used, in the "OFF" position the filter is in

"Bypass Mode" and only a 220 µF capacitor sits on the line. When

activated, the stage selector is kept at the halfway point at the

output of the 2nd 741 Op amp as this allows for much filtering but with

enough outside audio being passed through to be able to adjust the VFO

knob on the rig.

When an incoming CW signal is set at "zero-beat" I can then switch the

output to four-stage mode using all the Op amps.

If the received CW audio is clear or even piercing then the filter is

working. Since this filter is extremely narrow, some "ringing" (which

sounds like noise played underwater) may be produced.

The provided schematic has component values set to provide a frequency

response filter the incoming audio at around 750 Hz.

The "shoulder" of the response curve is wide enough to allow

frequencies 50 Hz in either direction with audibility. (700-800 Hz)

If you have a different "Side tone" on your rig than 750 Hz, you will

first need to zero-beat the signal in bypass mode first, use

the RIT on your receiver to "fake" the received tone match 750 hz.

This will allow you to enjoy the benefits of the filter.

So far the low capacity dollar store 9 v dry-cell has provided filter

power for hours, the circuit's current drain is in the mA's, so I can

imagine a good Alkaline battery to last a long time.

If you use a Lithium 9 v battery, you can escape the risk of battery

leakage and have a viable accessory that will stick around for years.

Here are my suggested steps in construction:

• Study the

schematics

• Calculated the

parts needed

• Hunt for spare

parts and purchase the ones still needed... Please consider the cost of

parts together as this may cost more than a pre-built version

• Important: Try

to Build on a bread-board first! This will allow for changes and help

you determine the project's usefulness

• Construction

either with a perf-board or with a custom etched PCB

• Testing of board

• Enclosure prep,

switch mounts and wiring

• Finalization,

mounting and cosmetics.

The builder might consider adding a gain amp at the end and a volume

reducing resistor network before the first capacitor to address

operating level deficiencies.

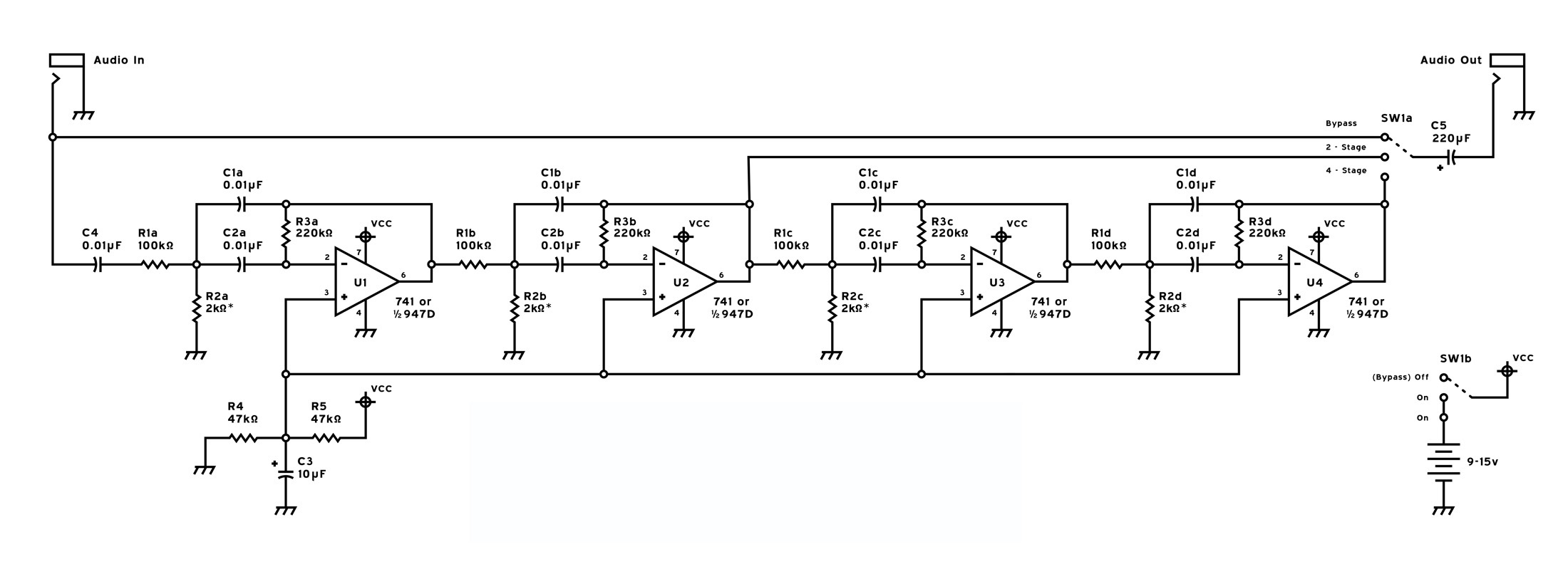

Schematic:

The

layout is actually easier than it looks. There are just four of the

same filter cascaded.

Circuit

description:

I cannot take full credit for this circuit, I used various reference

sources such as the ARRL Extra Class License Manual, and a GL Tab book

on Practical OP Amp Circuits.

The filter runs off of 9 v-15 v, draws only (est.) 3 mA and can either

use four 741 op amps or in my case, (2) 947D dual op amps, but others

Op amp variations will work.

The Op amps are configured with a "bandpass" topology, using a

"Twin-Tee" Resistor-Capacitor network.

The external components are what determine the operational

characteristics of the op amp and high quality and close tolerance

components must be considered.

C4 in front

decouples the incoming audio signal.

R1 determines gain

and is compared to the +/- voltage reference input on the

"non-inverting" side (+), those values R4 & R5 must be equal but

do not have to be an exact value related to the rest of the circuit.

Cutting R1's value in half to get the value of R4 & R5 work

fine.

C1 & C2 and R3 are the resonance

tank that determine the center frequency.

Though the active

band-pass frequency must be determined by R1-R3, so creating a variable

frequency response control is out of the question.

R2 will determine

the bandwidth to a degree and if only one stage is to be used that may

be a nice feature.

You can vary this

value to give you a controllable width of the final passband.

This project uses four stages to hone in the passband and is quite

effective with CW signals.

Using more stages will subsequently add more filtering, but in the

bargain, a "ringing" will become more evident, and eventually the

desired signal will distort.

The ringing on this one is not too bad and if it is evident it sounds

more like a signal that was "put under water". There has to

be an increase in out-of-passband signal energy (other signals) to

cause this effect.

As you can see, the voltage comparator network: R4 & R5 is

shared between all stages and cuts down on parts and connections.

C3: a 10µF electrolytic cap was included for AC signal blocking to

prevent a spurious oscillation.

A 100-400µF electrolytic cap must precede the output to decouple the

output.

As far as functionality and controls are concerned, this is the

builder's choice. I went with a DPDT switch for circuit

power, using the other side to bypass the audio when "OFF".

A SPDT switch is used to choose between the output for the two stages

and a total four stages.

You can even talor the "envelope" of the passband by allowing the end

two phases to have a wider pass, letting in just enough outer band

audio to keep you from getting lost when spinning the tuning dial on

your rig.

A note about the chosen resistor-capacitor values: first, if choosing

smaller cap values (like the 680 pF) will thus cause the resistor values

to go up to satisfy the equation.

When the resistance goes up, the audio power going though will be cut

and your total volume gain will be small.

You will then have to add another amplifier circuit such as an LM386 IC

based one to re-gain the audio volume.

Higher values of caps, like above 0.2µF will give you lower resistor

values, allow more audio power to run though, but will cause possible

distortion and too much current flow to the op amps.

This is why experimentation is suggested to be done on the breadboard

or in a simulation program like LTSpice

first.

I chose 0.01µF's since I had a handful of them laying around. This

value works fine, but my final volume is a little low, and I cannot

allow too much AF volume from my rigs before the filter becomes either

non-responsive or distorts with large signals.

By using a potentiometer for R2 AND using that part in series with a

low value resistor like a 500 ohm (to prevent a short) will allow you

to tweak the bandwidth and R2 value to match your "sidetone" signal -

this will allow you to use fixed resistors. You can however use four

trim-pots if money is not an issue.

The formulas can be found in the ARRL's 8th

Edition Extra Class License Manual on pages 6-7.

Also check this info out at Radio-Electronics.com... where you can get some extra theory information.

C will be both C1 and C2 in farads

F = Frequency in Mhz

Q = (sharpness of the filter skirt) should be less than 10

G = (Gain) should be 5 or less

R1 = Q / G x 2 x π x F x C

R2 = Q / (2 x Q² - G) x 2 x π x F x C

R3 = 2 x Q / 2 x π x F x C

• First choose a

capacitor value, 500 pF - 0.2 µF

• Choose a

frequency close to the "sidetone" of your transceiver. New rigs allow

you to set the frequency.

Applications such as CWget

are useful in detecting your side tone's frequency using your PC's

sound card.

• Calculate and

choose resistors close to those values. Use series or parallel values

where necessary.

• Start off with

one stage on the breadboard first.

• Use a variable

potentiometer for R2 with a value of at least twice the required

resistance or more to allow for tweaking.

• Measure this

value with your ohm meter to get fixed values. Use trim-pots for final

construction if desired.

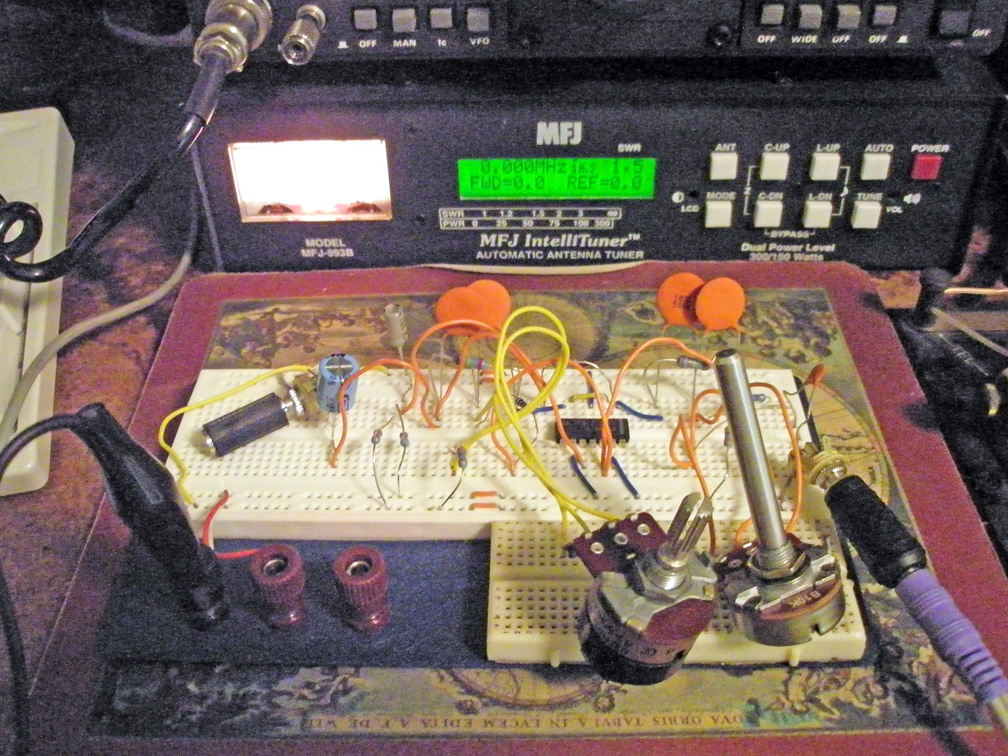

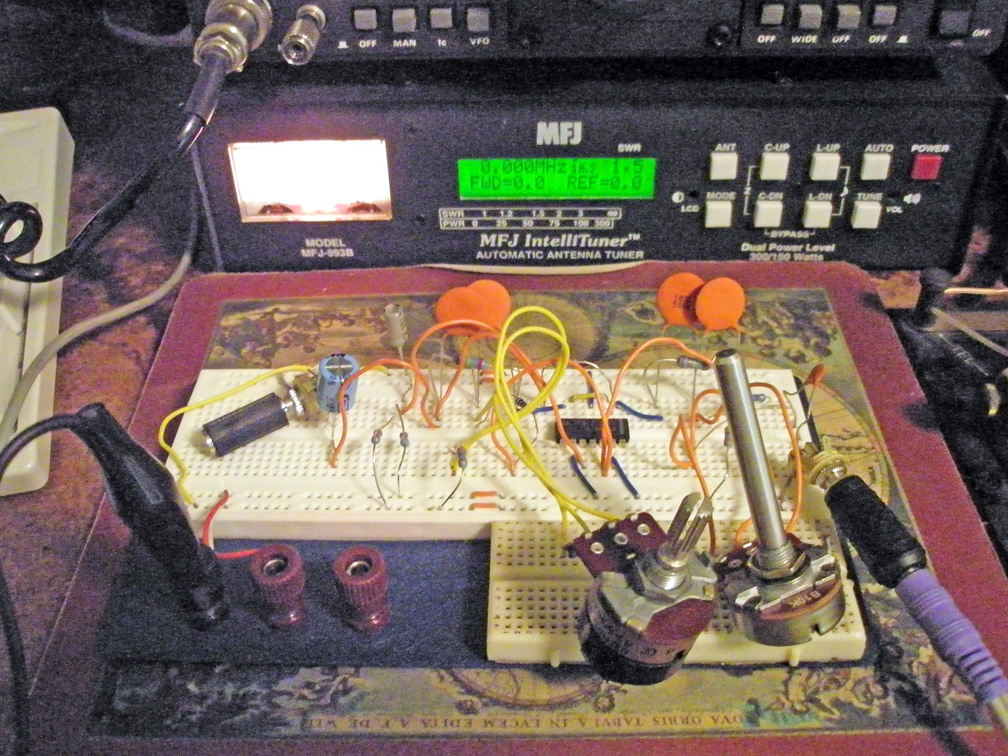

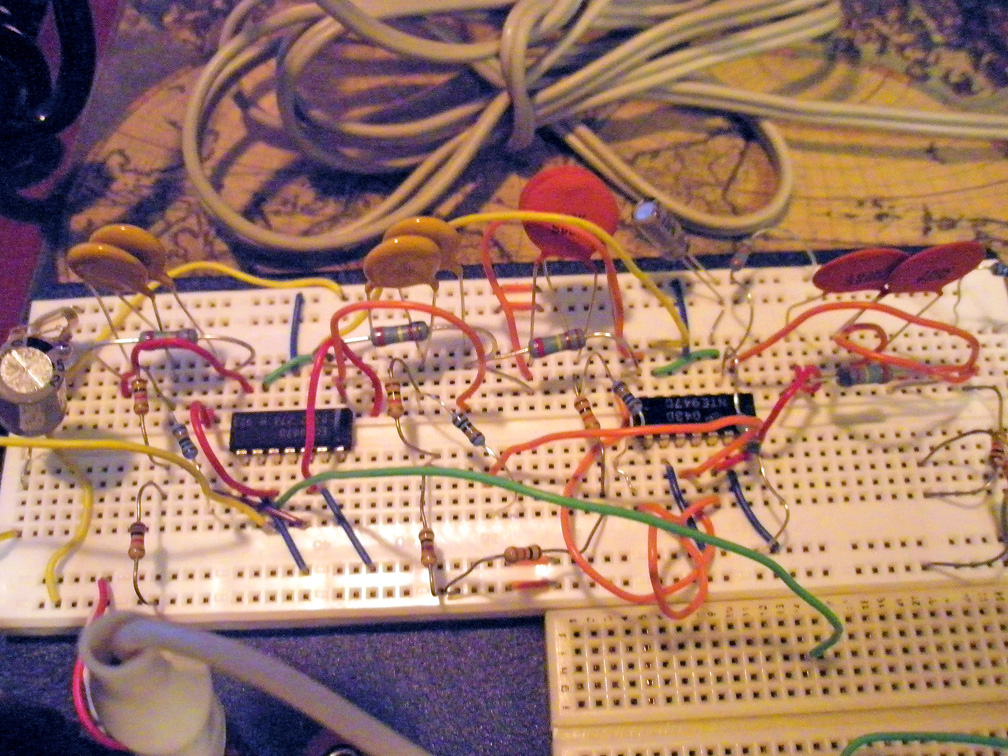

My first

setup on the breadboard:

One then two stages were

breadboarded and values adjusted with potentiometers.

This is

where I delveloped my own version of a very common project. By using

potentiometers on different parts of the circuit, my initial goal was

to make the frequency passband variable and not the bandwidth. However

the nature of the op amp and the "Twin-Tee" RC net required that many

values separately determine the center frequency. I had to settle for a

close match to the 732 hz sidetone that my current rig produced. The

pass band would end up being 60-100 hz and would allow for deviation

anyway.

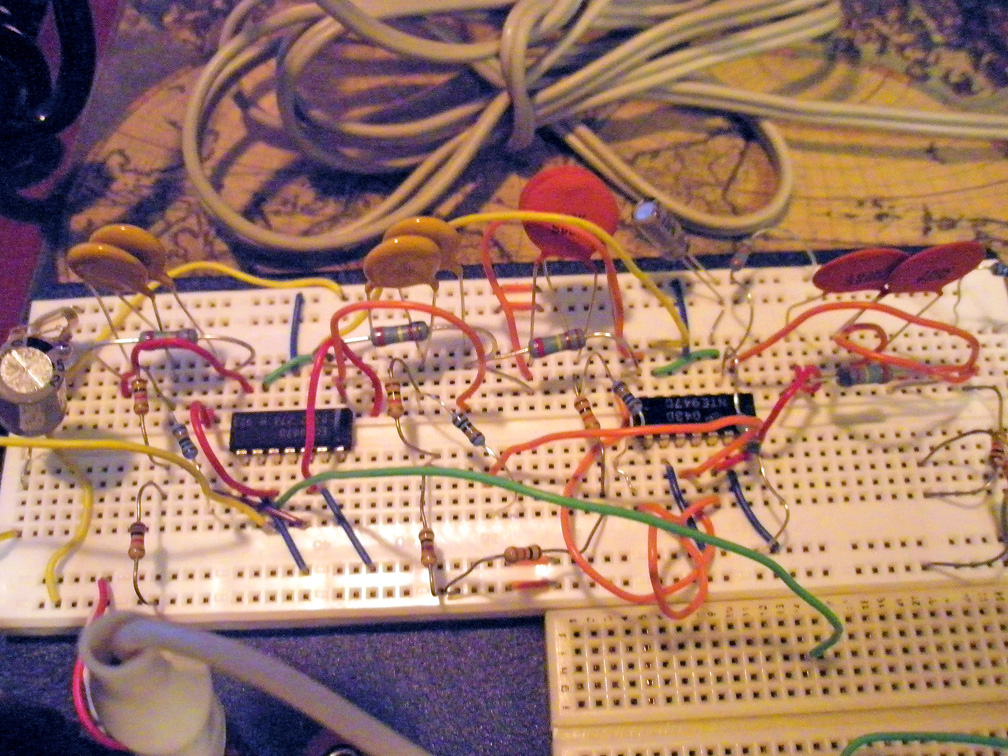

The whole

circuit in action with fixed resistors:

Here

is a good time to work out all the kinks.

The entire circuit was

re-constructed on the breadboard with fixed-resistor values that match

that of the potentiometers when adjusted.

Project

shown connected to audio source.

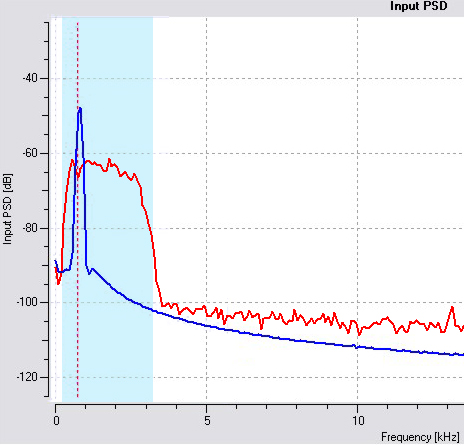

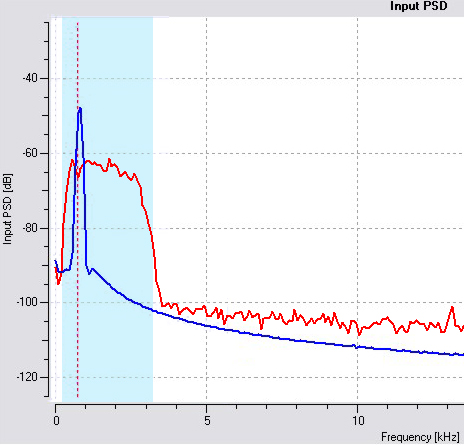

Testing with PC

based audio anaylizer:

This

setup allowed me to get the values right where I wanted them.

Though nothing beats the equipment between your ears!

Testing revealed that the center

frequency was finally at 750 hz, there was the -6 dB

reduction knee at 718 hz and 782 hz and dropped off very rapidly after

that.

40 dB to 60 dB attenuation by 685 hz and 815 hz (roughly) and a 3 dB

gain on the center frequency.

It was found that the noise floor or overall noise of the stop bands

(ouside range) had a potent effect of desensitizing the filter. Sronger

signals caused distortion, so starting with a lower output AF volume

setting is suggested.

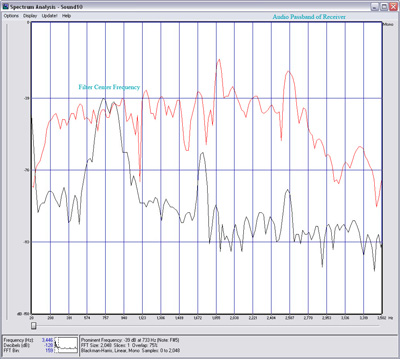

This

is a screen capture of the analyzer.

The shaded area represents the receiver's AF passband.

The Red line is sampled from the original audio signal.

The Blue line is sampled from the filter output.

The transceiver's side tone was used as the test tone, and the noise

level was such that it very well buries the tone in the original audio.

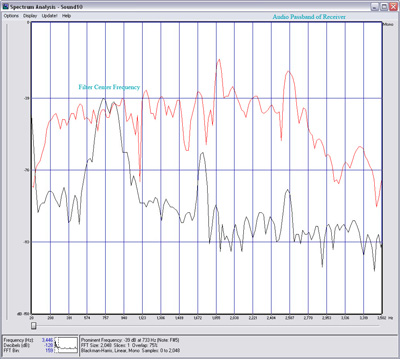

Later: another test on 05/17/08

was done using a place on the 40 m CW band. Click

here to listen to an audio sample...

The Kenwood TS-130SE was placed in the 3 kHz wide SSB mode to allow a

lot of noise and adjacent signals in.

You should be able to barely hear the CW letter "D" (-..) in the audio,

this signal was pre-tuned to match the sidetone of the rig at roughly

732 hz.

The filter set at 750 Hz would have no problem with the sidetone.

You will first hear the bypassed audio for a few seconds, then with the

filter in four-stage operation, then in two-stage to allow more audio

in, then back to bypass mode.

The screen capture below was derived from parts of the audio sample

analyzed in Sound Forge.

This

is a composite of Sound Forge's spectrum analyzer's screen capture and

is a more comprehensive analysis of the accumulated audio component

amplitudes.

The Red line is sampled from audio that was directly from the receiver

in Bypass mode on the filter.

The Black line shows the filter in action with all four stages.

This scan more relects the more

extreme conditions of the audio sample; heavy QRM/QRN and a high noise

floor. The level of attenuation is impressive!

Two curious anomolies exist that I would like to resolve. 1) The

extremely loud "Ker-Chunk" that occurs when the circuit is powered.

There is a large capacitor accross the audio output but there must be a

way to shunt or initially quell this artifact as it is unpleasant to

hear when constantly bringing the filter in and out. A build-up circuit

to bring in the circuit slowly could be added.

2) There seems to be some type of harmonic filter response that is seen

in a broader spectrum, a byproduct of the simple RC configuration. As

with any harmonic the level decreases as the frequency increases,

though this is a harmonic based on band passing and not a present tone.

This occurs at evey 5 kHz interval, but also at 2.5 kHz & 1.7 kHz.

However this seems to be all acceptable as there is no audible evidence

perceived. An additional low-pass filter element can be added.

I also request that if anyone

wishes to build an etched PCB version of this circuit, where less

wiring and soldering are to be done, or even an SMD version, I'd be

interested in getting an extra PCB in hand.

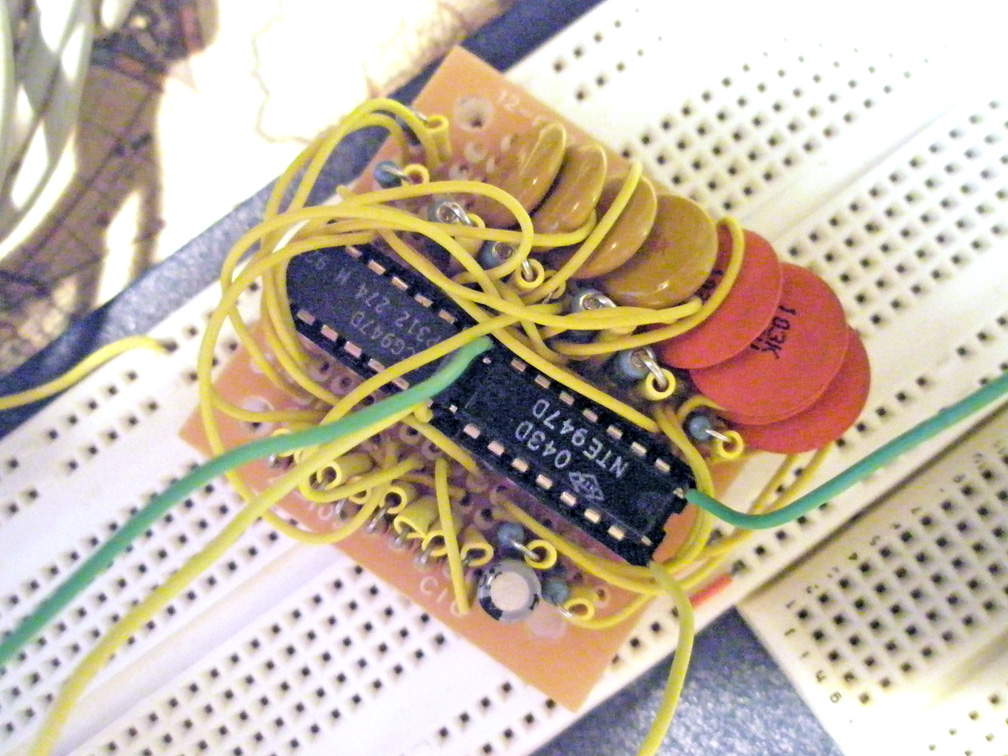

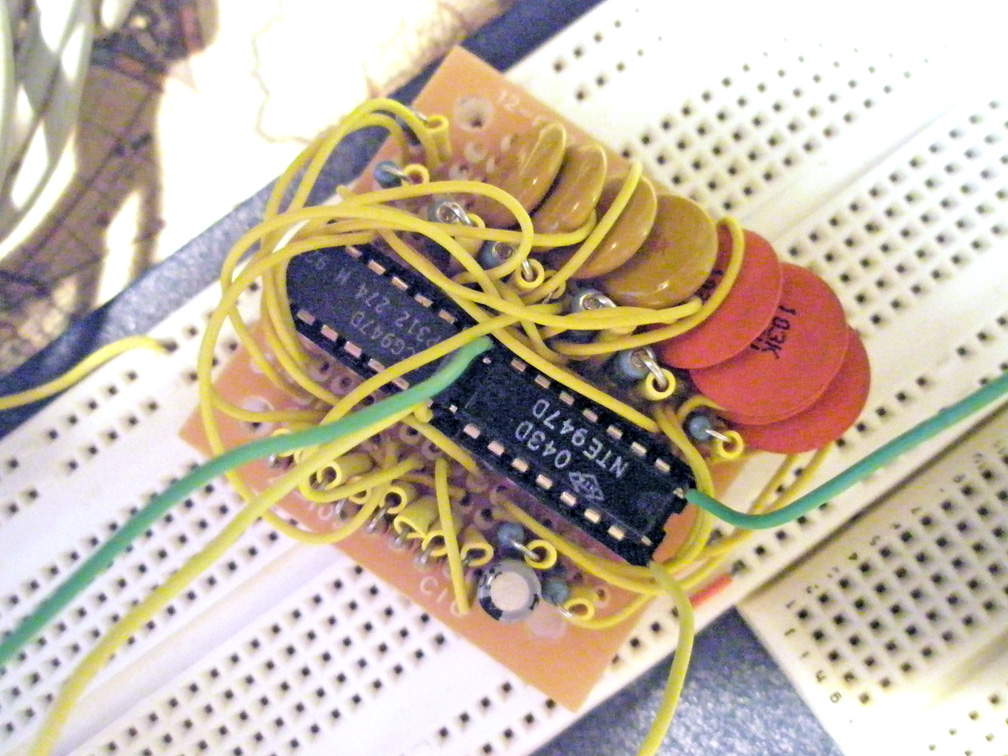

Construction of the

circuit board:

My wife is never too happy

when it's time to turn the kitchen into the lab...

Every

builder must determine what kind of construction and housing methods

are best for them.

Good construction techniques learned from elmers and from the manuals

are a must.

Proper care must be taken when working around larger 12 v power

supplies and RF shielding implemented around the final project.

New circuit board attached to

breadboard for testing.

It's a

good idea to run a "smoke test" and test the circuit once soldered to

find any mistakes.

Maybe even adjust component values, as tolerances and values can change

during installation.

Shortening lead lengths and placing components closer together can

augment stray capacitance values.

The bottom of this board feels like it has about a 1/4 lb of lead! This

is the "dead-bug" method of construction.

Note that smaller capacitors can be used along with 1/4 watt resistors.

Testing back on rig shows

that the center frequency moved up 10 hz.

This is to be

expected and allows you to go back and augment parts.

Housing:

Holes drilled for switches

and jacks... then the circuit board was wired to the switches.

I chose a

small mint tin for the enclosure, but I really didn't know going into

this project, how much space I needed when the project was started.

I purchased the switches at the end for being small and durable and I

had plans to use an exterior jack for power with Powerpole connectors

but discovered that a 9 v would fit neatly at the end.

The current drain is very low, so a dry-cell should work quite a long

time.

Ensure that the container you are using have conductive properties, the

outside of this container has some kind of clear paint.

Everything fit neatly... This

was by accident I assure you!

The lid actually closed!

Providing an RF shielded compartment.

Labeled and attached for work

to the transceiver.

Now it's

ready to use, and work it did!

I was amazed to be able to both "zero-beat" onto a caller quickly and

be able to isolate just who I wanted, while cutting out all kinds of

noise.

Even the extreme noise produced by my computer equipment.

Good

Luck on your own projects! 73, De Mike Maynard K4ICY

SKCC #8600

|